Trailer brakes aren’t just about stopping distance. They affect legal compliance, towing stability, and how hard your tow vehicle has to work. In Australia, brake requirements are generally tied to a trailer’s GTM (Gross Trailer Mass) and related ADR guidance.

This guide covers:

- When trailer brakes are required (by GTM)

- Electric vs hydraulic braking systems (and where EOH fits in)

- What a breakaway system is and when you need it

- How to choose and set up a brake controller

1) When are trailer brakes required?

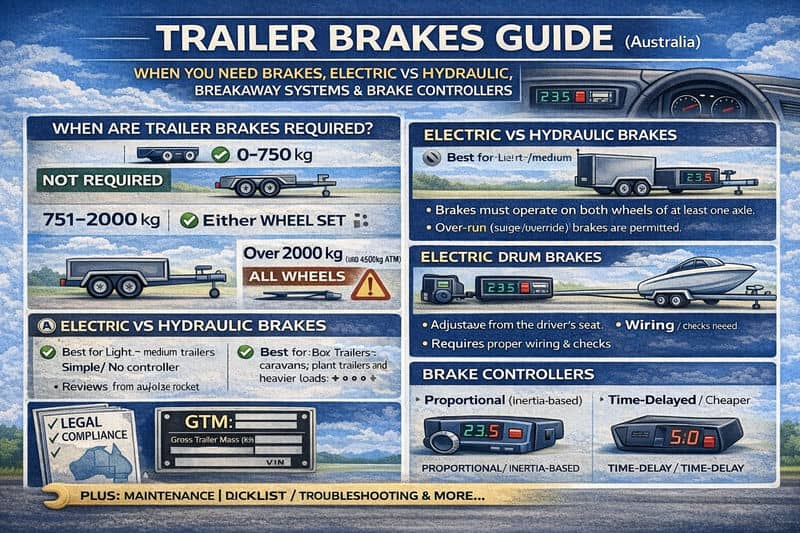

In most Australian guidance, brake requirements are based on GTM. The table below is a practical summary used widely across Australia. Always confirm your trailer’s compliance plate (GTM/ATM) and check state-specific requirements if you’re unsure.

| Trailer GTM | Minimum brake requirement | Breakaway required? |

|---|---|---|

| 0–750 kg | Generally exempt from fitting brakes | No |

| 751–2000 kg | Brakes must operate on both wheels of at least one axle. Over-run (surge/override) brakes are permitted. If not over-run, braking must be adjustable via a control signal from the tow vehicle. | No |

| Over 2000 kg (up to 4500 kg ATM) | Brakes must operate on all wheels of all axles. Must not be an over-run style system. Braking must be adjustable via a control signal from the tow vehicle. | Yes (must apply and remain applied for at least 15 minutes) |

Tip: If you’re towing near the 2000 kg GTM boundary, plan your brake system and tow vehicle wiring early. It’s much cheaper to do it once, correctly.

2) Trailer brake system options (and what they’re best for)

A) Over-run / surge brakes (mechanical or hydraulic)

How it works: The coupling compresses under deceleration, applying braking force automatically.

Best for: Light-to-medium trailers (commonly within the 751–2000 kg GTM range).

- Pros: Simple; often no in-cab controller required

- Cons: Less adjustable; can feel “grabby” downhill; reversing may need a lockout

B) Electric drum brakes

How it works: An in-cab brake controller sends current to an electromagnet inside the drum to create braking force.

Best for: Box trailers, caravans, plant trailers and heavier loads where in-cab control matters.

- Pros: Adjustable from the driver’s seat; good control; widely supported

- Cons: Requires proper wiring and periodic inspection/adjustment

C) Electric-over-hydraulic (EOH)

How it works: The controller drives an electric pump to generate hydraulic pressure for disc or drum brakes.

Best for: High-demand towing (often caravans/boat trailers) where consistent braking and strong modulation are needed.

- Pros: Strong braking feel; excellent modulation; often preferred with disc brakes

- Cons: Higher cost; more components; controller compatibility is critical

3) Electric vs hydraulic: which should you choose?

- Want simple and you usually tow within 751–2000 kg GTM → over-run can be suitable

- Need in-cab adjustability (changing loads, better stability control) → electric is typically the go-to

- Want disc brake performance with in-cab control → consider EOH

Real-world advice: If your load changes often (tools one day, materials the next), electric brakes with a proportional controller usually offer the smoothest, safest towing experience.

4) Breakaway systems: what they are and when they’re required

A breakaway system automatically applies the trailer brakes if the trailer becomes disconnected from the tow vehicle. For heavier trailers, it must be capable of immediate application and holding the brakes for at least 15 minutes.

Typical breakaway components

- Breakaway switch (pull-pin) and lanyard

- Dedicated breakaway battery (and charger/charge line)

- Wiring into the brake circuit

- Secure mounting and weather protection

Common breakaway mistakes

- Attaching the lanyard to a weak point (or looping it around safety chains)

- Neglecting the breakaway battery (flat batteries are a common failure)

- Storing the pin loosely (accidental activation can drain the battery or create risk)

5) Brake controllers: types, selection, and setup

If your trailer uses electric brakes or EOH, you generally need a brake controller in the tow vehicle.

5.1 Controller types

- Proportional (inertia-based): Adjusts braking force based on deceleration. Smoother and safer.

- Time-delayed: Ramps up braking after the pedal is pressed. Often cheaper, but less refined.

5.2 What to check before you buy

- Your trailer brake type: electric drum or EOH (controller must support EOH if applicable)

- Tow vehicle wiring: proper brake output wiring and suitable trailer connector

- Mounting requirements: some proportional units require specific angles/positions

5.3 Basic setup (a safe starting point)

- Start with a moderate gain setting

- Test at low speed on a quiet road (around 20–30 km/h)

- Increase gain until trailer braking is supportive without easily locking wheels

- Re-test whenever the load changes (weight distribution affects braking)

Pro tip: The manual override lever/button is useful for stabilising a minor sway event, but it should never replace correct loading and safe driving.

6) Maintenance and quick troubleshooting

Electric drum brakes

- Inspect magnets, shoes, and drums

- Check wiring, plug pins, and earth/ground for corrosion

- If braking is weak: confirm controller output and voltage at the trailer plug

Hydraulic / EOH systems

- Check fluid level and leaks

- Bleed air from lines if braking feels spongy

- Verify actuator/pump operation and power supply

FAQ

Do I need a brake controller?

Yes, if your trailer uses electric brakes or EOH, you generally need an in-cab controller.

Are over-run brakes allowed on heavy trailers?

Over-run brakes are commonly permitted up to 2000 kg GTM. Above 2000 kg GTM (up to 4500 kg ATM), brakes must not be over-run style and breakaway is required.

How often should I test breakaway?

Test periodically and before long trips. Also check the breakaway battery health and charging.